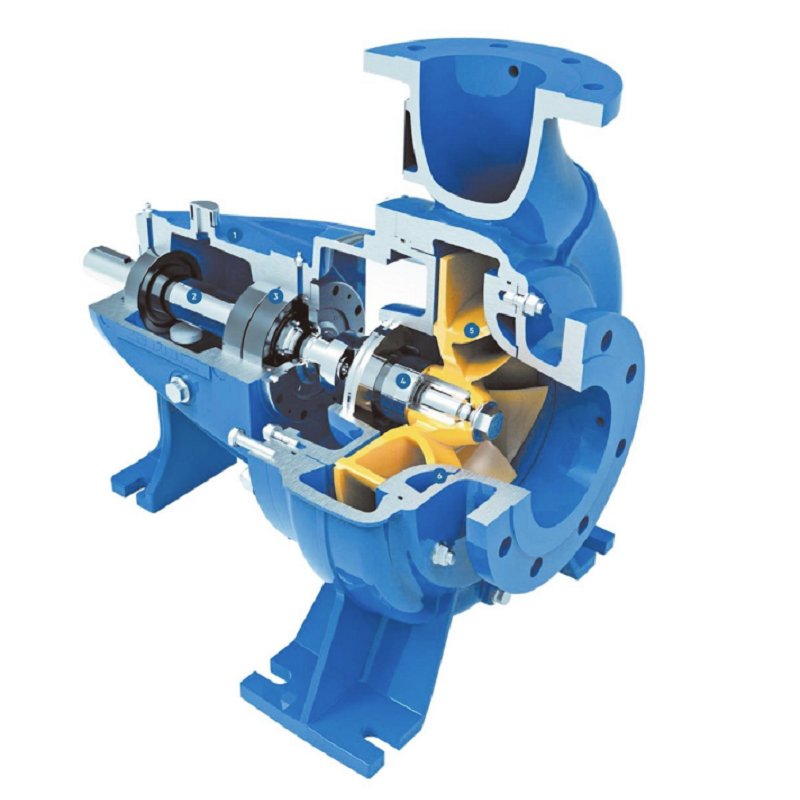

1 BEARING SUPPORT

• Single casting with integrated lantern

• Only seven bearing support sizes for the entire series

2 SHAFT

• Ensures minimum shaft deflection and low mechanical vibration

3 TOUGH BEARINGS

• Long service life

4 SHAFT SEALING

• Single mechanical seal for stock conveyance without sealing and rinsing water

• Double mechanical seal

• Dynamic seal

5 IMPELLER DESIGN

• Open, semi-open or closed

• Special impeller for tomato paste and fruit concentrate

6 WEAR LINING

• One wear lining to protect the pump casing

1. High efficiency,energy-saving

The average operating efficiency of an ordinary paper pulp pump is 3-10 percentage points, Energy saving, saving up to 15-30%. 2. Good cavitation performance, long service life

Real-life can increase 2-3 times than ordinary paper pulp pumps.

3. High concentration, without plugging.

4. Reasonable structure, easy maintenance

The former head part is, the door structure, pipeline maintenance without disassembly, just move the motor backward, you can disassemble and repair the pump.

5. Wetted parts are made of cast iron, cast steel, and stainless steel for the user to choose.

6. The pump can be within the scope of 5 ~ 40℃ environment temperature and the inlet pressure under the condition of less than 1330 pa, allowing continuous work for a long time.

Working principle:

It is guaranteed that a rotary vacuum pump can start normally in the low temperature of winter. It is applicable to vacuum packaging, vacuum-free. It also can be used alone, also can be used as a booster pump, diffusion pump, molecular pump, and backing pump.

Besides, it can be used for vacuum metallurgy, vacuum welding, vacuum impregnation, coating, vacuum drying and chemical pharmaceutical, electric vacuum components and other industrial vacuum operation.