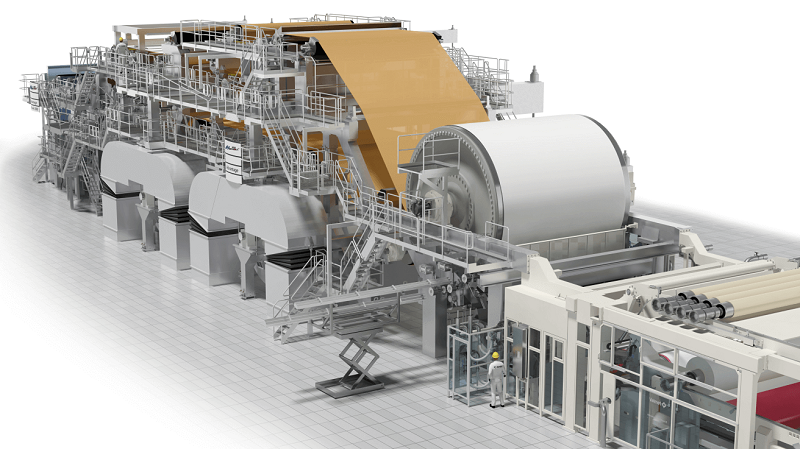

Tissue Paper machine Longitudinal direction from the headbox inlet to the end of reeler, horizontal direction from operating table on the operation side to the end of main drive motor on the driving side, including the direct control of all electrical and pneumatic control equipment in above scope.

1. Raw material: virgin pulp, wood, bamboo, reed, wheat straw, cotton, and bagasse, etc.;

2. Output paper: top-quality toilet paper, tissue paper.

3.Capacity: 30-200 tons per day(24hours);

4.Net paper width: 1000-3200 mm;

5.Output paper weight: 13-40 gsm;

6.Working speed: 50-1800 m per min;

7.Design speed: 100-2000 m per min

8. Drives: AC frequency converter, adjustable speed, section drive.

The headbox for this machine is a crescent-shaped headbox that is in the international advanced level of this industry. Headbox is composed of pulp distributor, main box and rectifier tube bundle device, box adjusting device, lower lip plate, upper lip plate, upper lip edge straightness adjusting device, upper lip plate opening adjusting device and sidewall plate.

The headbox is made of stainless steel (expect bearing , worm gears and worm gearbox). Among them, the distributing main tube, rectifier tube bundle upper& lower lip plate contact with pulp parts are made of 316L material, and the rest and made of 304 stainless steel.

Yankee dryer

Standard grooved Steel Yankee dryer

Dimension: ф3660mm×3150×4100mm (diameter *face width*gauge)

Material: low carbon steel welded surface Spraying

Hardness: HB600-700°

Design pressure: 1.0Mpa (Working pressure 0.85Mpa)

Siphon and heat insulation material:304 stainless steel

Dynamic balance grade: G6.3

This machine is equipped with the type of respiration hot-blast air hood, which is divided into two sections. The front part is the wet section hood and the rear part is the dry section hood. The air blowing and exhaust steam are all orifice structures. Two sections of steam can be pneumatically opened. The edge part between the hood and the dryer is closed by a silicone rubber sealing strip. The effective drying angle of the hood is 220°, the hood provides about 20% drying capacity for the dry section.

The hood design of this structure not only improves the drying ability of the drying section but also ensures that the hood will not drip on paper under extreme conditions. The main body of the hood is welded with stainless steel, the bracket and framework are made of low carbon steel and covered with a 2m thick aluminum sheet.