Sludge is the terminal product of wastewater treatment in the papermaking process. Each ton of recycled paper produced 700kg of sludge with 65 % water content. Sludge production is 5 ~ 10 times of municipal wastewater treatment plants of the same scale. At present, the basic ways to treat papermaking sludge and waste residue are landfill and incineration, which will cause secondary pollution to the atmosphere, soil, and groundwater.

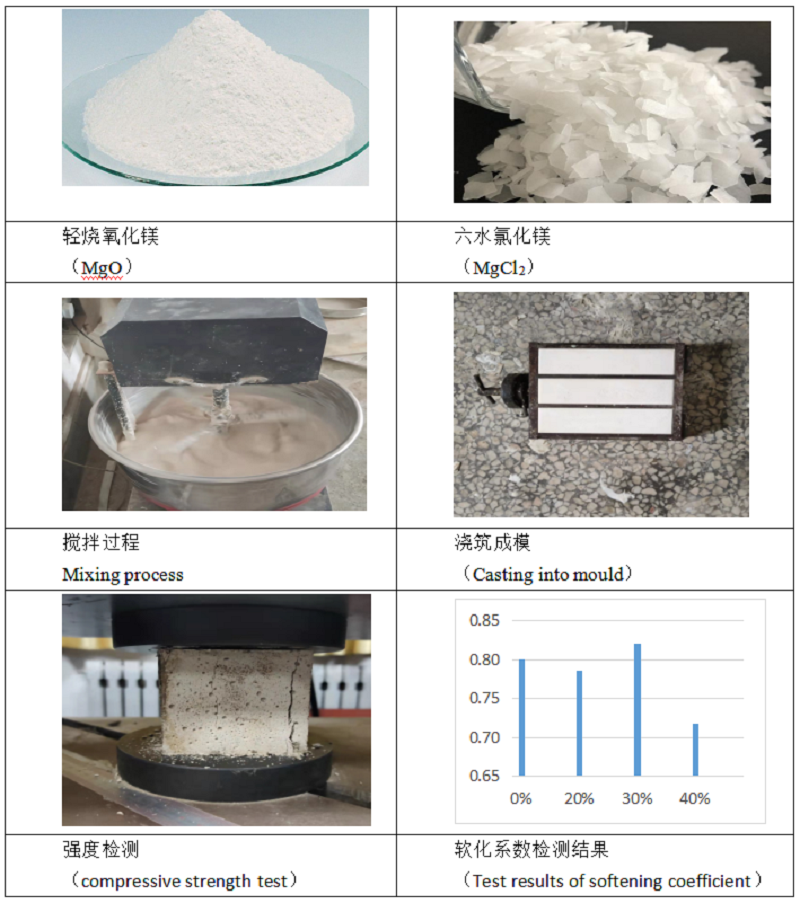

The manufacture of lightweight partition boards fully combines the advantages of paper sludge and magnesium oxychloride cement. Papermaking sludge contains lignin, fiber, and other components, which can effectively enhance the toughness of cement. At the same time, magnesium oxychloride cement has the advantages of low alkalinity, good resilience, fast setting speed, and strong adhesion. The strength of the composite wallboard can reach 10 MPa, and the bulk density of the wallboard is 70 kg / m3, which meets the engineering application requirements of light wallboard. In general, on the one hand, the use of a large amount of paper sludge solves the problem of environmental pollution from the source; on the other hand, through the rational use of magnesite resources to meet the needs of building materials, in line with the concept of a green cycle of dual carbon construction and development.